|

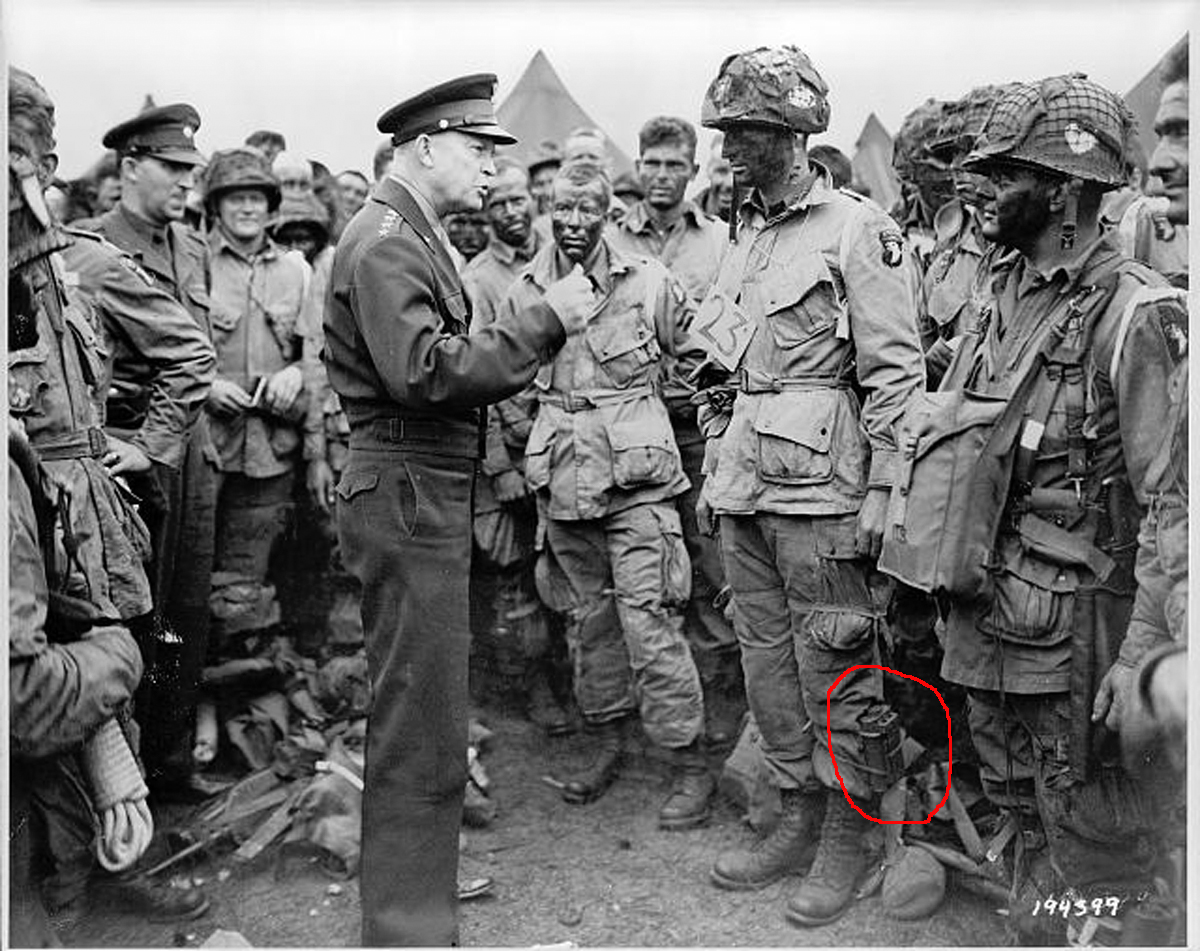

Grenade, Hand, No. 75 Anti-tank

Mk. I

This grenade was officially adopted for British

service in June 1942. It was

adopted for use by American Airborne troops in the drops on Normandy in

1944 and perhaps after. It

is commonly known as the “Hawkins Grenade”.

The body is a 1 pint capacity flat

tin with a short neck and screw cap at one end.

The igniter holder is made of tinplate and formed to make two

igniter pockets. The holder

is then soldered to the centre of the body.

Slots are cut into the holders on the upper side and tabs at the

end of the pockets that are bent in to retain the igniters in position.

Support brackets are soldered onto either end of the body.

The striker plate attaches to the support brackets by tabs.

The striker plate has a transverse groove formed in the centre

that projects out the bottom and forms the striker.

The striker groove is positioned directly above the slots in the

igniter holder. The body is

filled with Nobels Explosive No. 704B plus four exploders, Burrowite

plus four exploders, or a combination of 1/3 Burrowite and 2/3 Nobels.

The exploders are cylindrical pellets 7/8 inch diameter and three

inches long of Polar Dynamite and are placed in the body at the lower

end directly under where the detonators would be.

The igniter assembly consists of an

“Igniter, No. 75 Grenade Mk. II” and a No. 27 detonator.

The igniter operates by chemical reaction.

It consists of a tinplate tube closed at one end by flattening

the tube. A circumferential

groove is formed on the inside of the tube about half way down.

A lead washer is pressed into the groove inside the tube.

The hole in the washer is filled with a composition of potassium

chlorate, sugar and charcoal.

A small glass vial containing a mixture of 93% sulphuric acid and

7% nitric acid is contained above the washer in the closed end of the

tube. Cotton wool packing

protects the vial. A thin

rubber sleeve is rolled onto he open end of the igniter to provide a

means of attaching the detonator.

The grenade is painted buff.

The manufacturers mark, date of manufacture and designation are

embossed into the side of the grenade opposite the striker plate.

Filling details are stencilled

onto the bottom of the grenade.

For use the igniter must be prepared

by inserting the detonator, open end first, in the open end of the

igniter until it rests on the lead washer.

The rubber sleeve is then rolled down to hold the detonator in

place. The igniter is then

placed in one of the igniter pockets of the grenade detonator first.

The tab on the igniter pocket is then bent in to hold it in

positon. The operations are

then repeated for the other igniter pocket.

When properly done the glass vial portion of the igniter is

directly under the slots in the igniter pockets.

The grenade can then be placed as a mine or thrown in the path of

a vehicle. When the grenade

is run over, the striker plate bends and

forces the striker groove down onto the igniter assemblies.

When the glass vials are crushed the acid comes into contact with

the composition in the lead washer.

A chemical reaction occurs and a flash produced that initiates

the detonator and causes the grenade to explode.

|