This mechanism operates on a hair trigger

principle. It is operated by

a trip wire attached to the spindle.

It was intended for use with movable objects, windows, chairs,

pieces of equipment or weapons, souvenirs or any other item that was

likely to be moved.

The base assembly contains a 1.7 grain detonating

cap, No. 27 service detonator and standard C.E. primer.

It is screw threaded to screw into the upper housing.

It is common to all the trip mechanisms.

As an alternative a fuse adapter is provided that screws into the

base of the assembly that allows either instantaneous or safety fuse to

be crimped in and ignited by the mechanism.

There is an “L” shaped bracket that can be used to

fix the mechanism. There are

four holes in the back of the bracket so it can be nailed into position.

On the lower bracket a hole in the centre is used to attach the

bracket to the mechanism.

The upper housing fits on top and the base assembly screwed up through

the hole to hold the device.

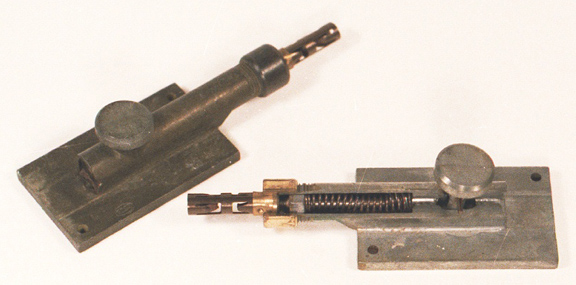

This mechanism operated on the ball release

principle. It could be

operated by a direct downward pressure, release of pressure, or by a

twist applied by means of a trip wire.

The

upper housing contains the operating parts of the mechanism.

It is made of an alloy in two parts, an inner casing and an outer

casing. The inner casing

houses the firing pin, firing pin spring and retaining ball.

The firing pin is held by the retaining ball riding in a groove

in the striker and a hole in the inner casing.

The outer casing is cast with a wider head and a central ring

around the lower half. The

outer casing fits over the inner casing covering the hole in the inner

casing and holding the retaining ball in.

The firing pin spring is compressed against the firing pin and a

stud on the interior of the top of the outer casing.

There are two holes, upper and lower, in the outer casing that

line up with the hole in the inner casing in two positions.

On the opposite side to the holes there is a “Z” shaped slot with

a setting stud screwed through the slot into the inner casing.

A safety bolt fits through both casings in the lower section.

Two firing pin springs are supplied with the

mechanism, one giving an operating force of 4 pounds, the other to give

an operating force of 12 pounds.

The base assembly contains a 1.7 grain detonating

cap, No. 27 service detonator and standard C.E. primer.

It is screw threaded to screw into the upper housing.

It is common to all the trip mechanisms. As an alternative a fuse

adapter is provided that screws into the base of the assembly that

allows either instantaneous or safety fuse to be crimped in and ignited

by the mechanism.

There is an “L” shaped bracket that can be used to

fix the mechanism. There are

four holes in the back of the bracket so it can be nailed into position.

On the lower bracket a hole in the centre is used to attach the

bracket to the mechanism.

The inner housing fits on top and the primer housing is screwed up

through the hole to hold the device.

This mechanism can be used for pressure, release,

or pull operations. To use

in the pressure mode, the setting stud is moved to the “PRESS” position

in the “Z” shaped slot.

Depending on the spring used a pressure of 4 or 12 pounds will push down

on the head, forcing outer housing

down and bringing the upper hole in the outer casing in line with

the hole in the inner housing.

This allows the retaining ball to move outward and release the

striker to move down under pressure of the firing pin spring to hit the

primer and fire the mechanism.

To use in the release mode, the setting stud is moved

to the “LIFT” position in the “Z” shaped slot.

Again, depending on the spring used, a weight of over 4 or 12

pounds is placed on the mechanism.

When the weight is removed, the spring will force the outer

housing up, bringing the lower hole in the outer casing in line with the

hole in the inner housing.

This allows the retaining ball to move outward and release the striker

to move down under pressure of the firing pin spring to hit the primer

and fire the mechanism. For

use as a pull mechanism, the setting stud is moved to the “PRESS”

position in the “Z” shaped slot.

A trip wire is attached to the central ring in such a manner that

a light pull on the wire will rotate the outer housing to the “LIFT”

position and since there is no weight to restrain it, the device will

then operate as a release mechanism.

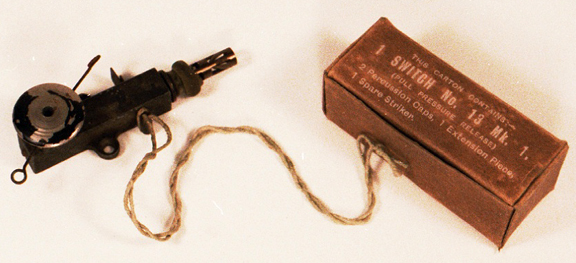

Trip Mechanism No. 6

This is a very simple mechanism, it consists of an

alloy housing that contains a spring loading striker.

A wire attached to the striker protrudes from the top of the

mechanism and is used to cock the mechanism.

The striker is held in the cocked position by the end of a

special composition wire.

There are two feet of the wire supplied with the mechanisms wrapped

around the mechanism when issued.

The wire fits through holes in the side of the housing and firing

pin. No other safety device

is fitted.

For use, a standard trip wire is attached to the

free end of the special composition wire.

A pull on the trip wire will withdraw the wire from the mechanism

freeing the striker to drive down under influence of the striker spring

to hit the percussion cap and fire the mechanism.

For the device to operate the wire had to be completely withdrawn

from the mechanism.

This was a simple igniter, used

normally to ignite safety or instantaneous fuse.

It was possible to use it as a pull switch.

This was available for use at the start of WWII and was used for

many years, examples dated 1953 have been noted.

It consists of a brass barrel

with threading on both ends.

On the top end it has a cap with a hole through the centre for the shaft

of the striker. On the other

end is a threaded cap to retain the fuse adapter.

A striker with spring is inserted with the shaft protruding out

the top and a safety pin fitting through the shaft.

The safety pin holds the striker in the cocked position with the

striker spring compressed.

Initially known only as the

"Pull Switch" this device was designed near the end of 1939 by Lt. Col.

Stuart Macrae of M.D.1 (Military Department 1).

It came about because the only device the British had to set off

a boobytrap with a trip wire was the standard service igniter, a device

actually designed to replace matches for lighting a length of safety

fuze. The service igniter

worked perfectly well for the purpose it was designed but left something

to be desired as a boobytrap device.

Lt. Col Macrae in fact designed

the pull switch from a shirt stud that worked in a way that he

considered quite clever. The

stud had a detachable head that remained firmly in place normally but

when a centre pin was pulled out could easily be removed.

The head was attached to a thin split tube with the end slightly

bulged out. The body of the

stud was a hollow button with another small tube projecting out from it.

The stud was assembled by pulling out the centre pin as far as

possible, pushing the split tube through the other tube until it passed

through and pushing in the centre pin again.

Pushing in the centre pin expanded the split tube so that it

would not pass through the other tube until the centre pin was pulled

out again. It was from this

small device that Macrae got the idea of how to design the pull switch.

Once Macrae had the idea he designed the pull switch in an hour.

The prototype was made the next day and two weeks later MD1 was

in full production of the switch.

It was a very successful design that worked perfectly from the

start. Over three million

were made during the war at a cost of 2/6d.

It is a measure of its success that it was not redesigned

throughout the war but remained in its original form.

The official description of the

switch was: "The Pull

Switch is a device to be used in conjunction with a trip wire for firing

a mine. It is particularly

useful for booby trap work.

Designed to operate when a direct pull of about 4 lbs is applied to the

release pin it fires a percussion cap in a holder exactly the same as

that supplied wit the Mk. III Service Igniter.

With the cap holder in position the switch measures approximately

4" overall by 5/8" in diameter and weighs 2 ½ oz.

It consists of a head into which is screwed a housing tube

containing a plug with a restricted opening.

At the other end of the tube is a screwed collar for attachment

of the cap holder. Inside

the housing tube is a striker head attached to a hollow spindle, which

runs inside a compression spring.

The end of the hollow spindle carries a small head which is

split, so that when it is compressed the diameter is reduced.

When this split head is forced through the small hole in the

housing tube plug, a spring loaded release pin at once enters and

expands the head so that it cannot return, although it is now under the

influence of the compression spring.

The device consists of a brass

tube threaded on both ends.

A threaded collar on the bottom end holds a standard fuze adapter with

percussion cap. The upper

end has a threaded housing that is fitted with the release pin and

spring. A brass plug with a

hole through the centre is fitted into the top end of the brass tube

before the housing is screwed on.

A striker and striker spring fit in through the bottom of the

tube. The split stem of the

striker fits through the plug up into the housing until the release pin

penetrates and expands the striker stem.

A safety pin fits through the housing and release pin preventing

it from moving. A split ring

is fitted through a hole in the end of the release pin so a trip wire

can be easily attached. An

anchor bracket may or may not be fitted by removing the collar and

slipping the bracket over the tube and replacing the collar.

The original pressure switch was

designed by Millis Jefferies (Later Major-General Sir Millis Jefferies,

K.B.E., M.C.) in early 1939.

His first pressure switch, originally designed for destroying railway

lines, was based on a large brass casting.

It used a conventional spring-loaded striker in a partitioned

barrel. The striker was

maintained in the cocked position by a steel rod that had been hardened

to the point of brittleness.

The rod was secured to the closed end of the barrel with a pin.

It ran through the partitioned off section and had the spring and

striker head after the partition.

A hole with a boss bearing was placed over the partitioned off

section. A plunger was

dropped into the hole so that its "V" end straddled the hardened steel

rod. A safety pin fit

through the boss and plunger preventing the plunger from being

depressed. While the

design of the switch was good, it was too heavy to be practical.

It was redesigned to become a device weighing only 6 ounces and

costing only 3/6d.

The pull switch as designed and

issued by MD1 was constructed of brass except for the steel rod, striker

head, and striker spring.

The barrel is cast as one piece with an enlarged section at the closed

end. The opposite end is

drilled out to a depth of about 2 inches to form the barrel.

The bottom of the enlarged section is flattened and is drilled

out from the bottom to form a partitioned section.

A hole is then drilled from the top for the plunger.

A small hole for the steel rod is drilled from the closed end

completely through into the barrel.

The barrel is threaded on the open end to fit a screwed collar.

The base plate is a 1/8 inch rectangular piece of brass that is

attached by two bolts to the flattened portion of the barrel.

There are five holes in the base plate, two countersunk holes for

the bolts, two in opposite corners to allow the switch to be screwed in

position, and one large one to hold the pressure plunger in transit.

The pressure plunger is turned out of brass with a stem and large

pressure head. The bottom of

the stem is slotted for a short distance and has the bottom of the slot

formed into a "V" shaped cutting head.

A safety pin passes through the stem.

The steel rod is assembled with

the striker head and striker spring.

It is passed through the hole in the barrel assembly compressing

the spring. It is then

pinned in the cocked position.

All holes into the partiioned section are then sealed with

sealing wax.

The Mk. II version of the pressure switch has a body and base cast from alloy in a single piece. A small boss is formed on the top of the body to accept the pressure plunger. The safety pin is fitted through holes in the boss and through the pressure plunger. Because of this design change the plunger is assembled to the body when issued rather than being held in the base plate as in the Mk. I version. In addition the switch has improved waterproofing

This switch was also designed by

Lt. Col Stuart Macrae of MDI.

It was another of the successful devices that worked correctly

the first time and needed no improvements throughout the war.

From design to full production took only two weeks.

About two million were made during the war at a cost of 2/3d

each.

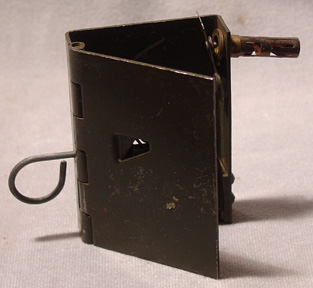

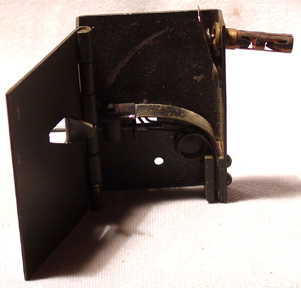

The switch resembles a small box

with a hinged lid. The main

casing is constructed of sheet steel and has a lid, hinged on the long

side of the box. There are

two punchouts in the body, one in the bottom that is rectangular and

bent up to form a bracket for the safety pin.

The other is in the lid and has an angled side forming part of

the release mechanism of the switch.

There is a hole drilled through the base to allow it to be

screwed or nailed in position.

A strong leaf spring with a hammer head mounted on the free end

is attached on the side of the box opposite the hinge.

An additional half length leaf spring is attached on top of the

leaf spring to give a stronger spring.

The springs are retained in position by two small bolts that

screw into a small rectangular plate over the end of the springs.

The hammerhead attached to the end of the longer spring has a

large hole drilled through the head to correspond with a hole in the

side of the case and a hole in the anchor tab.

The safety pin fits through the case, then the hammerhead, and

finally the tab to retain it in the cocked position.

The opposite end of the box has a hole to accept a fuze adapter.

A short piece of spring steel with a striker mounted is riveted

in position so that the striker is positioned over the hole where the

percussion cap of the fuze adapter would sit.

This piece also serves to keep the fuze adapter in position after

it is fitted.

The switch is painted olive

green with no other markings.

The switch may or may not be stamped with an "MD1" mark.

This is the original design of

the switch and is only known as the "Release Switch".

It was used prior to official adoption as a service store.

The switch that was adopted as

a service store as the No. 3 Mk. I is slightly modified from the earlier

release switch. This version

has the second shorter piece of spring steel shortened and an additional

wire spring fitted to give a stronger hit when released.

The switch is painted olive

green with no other painted markings.

The only other mark is the British Broad arrow marking.

The use of the switches is

identical. For use, it must

be cocked by drawing back on the hammer head until the safety pin can be

inserted and retain it in the cocked position.

At this point the pressure placed on the safety pin makes it very

difficult to remove. A fuze

adapter or spring snout is then inserted in the hole at the end of the

box under the firing pin.

The fuze is placed in position and the charge attached.

An object weighing at least 1.5 lbs is then placed on the top of

the lid. This forces the lid

down which forces the inclined tab on the lid to push the spring back

slightly. This action

releases the safety pin allowing it to be easily removed.

When removing the safety pin, if there is any resistance, the

switch is not laid properly and must be reset.

If the safety pin comes out without resistance, it is laid

correctly.

This switch was designed by

Experimental Station 6; a cover name for the SOE production

establishment. Originally

known as "Type 6 Pull" it was designated No. 4 Mk. I when it became a

service store in 1942/43.

It remained in service for a great number of years after the war,

being used well into the 1980's, and may still be in service.

Switches dated as late as 1984 have been noted.

The mechanism consists of a

brass body with a clip bearing two eyes attached near the bottom end.

The bottom end is internally threaded to accept a "Snout, Switch,

Capped Mk. 1". The top end

has two elongated slots opposite each other and has an internal

constriction formed at the bottom end of the slots.

The striker has a shoulder and firing pin formed at one end and a

rounded head at the other. A

safety pin hole is drilled through the rounded head.

A "U" shaped clip is formed in such a manner that the ends

conform to the rounded head of the striker.

When assembled the striker and

striker spring are put in through the bottom end of the body and forced

up through the constriction far enough so the head protrudes past the

top end of the body. The "U"

shaped clip is put over the head of the striker and the striker allowed

to move back into the body.

At this point the clip will not open enough to release the striker to

pass back through the constriction.

A safety pin is pushed through the slots in the side of the body

and through the hole in the striker head to ensure the device remains

safe.

The body is left with the

natural brass colour although a varnish is applied.

The body is marked in black with the designation, manufacturers

mark, date of manufacture, and lot number.

When the switch is set with a

trip wire, a tension is put on the line to pull back on the "U" shaped

clip so the safety pin will come out easily.

At this point the safety pin will be somewhere near the centre of

the elongated slots. With

the safety pin out: if a pressure or pull of six to eight pounds is

applied to the trip wire, it will pull the "U" shaped clip and the

striker with it, out of the body.

When the clip clears the top end of the body it will release the

striker to move forward under pressure of the striker spring.

The firing pin strikes the percussion cap and sets of the trap.

This switch was designed by

Experimental Station 6; a cover name for the SOE production

establishment. Originally

known as "Type 6 Pressure" it was designated No. 5 Mk. I when it became

a service store in 1942/43.

It remained in service for a great number of years after the war,

being used well into the 1980's, and may still be in service.

It has been in British and Canadian Service and possibly with the

American OSS as "Firing Device-Pressure Type A3".

The switch consists of a steel

case with a hinged steel lid fitting inside the case.

A zinc alloy body is fixed inside the case by a countersunk bolt.

The end of the body is threaded to accept a " Snout, Switch,

Capped Mk. 1". There are two

holes in the bottom of the case for use in securing the switch.

Two studs on the bottom of the case keep the sear springs in

position. The lid has a

centre threaded hole to screw an extension into.

The striker is formed with a shoulder and firing pin on one end

and a detent on the other.

The sear is formed of steel and has two studs riveted on to correspond

with the studs on the case to retain the sear springs.

A safety pin passes through the case, body, and striker to ensure

the device will not fire when it is in position.

An extension rod is made in two

parts, a brass socket that screws into the top of the lid and a steel

rod that screws into the socket.

The extension is adustable in height by about one inch by varying

the amount that the rod is screwed into the socket.

If a shorter extension is required, the socket may be used

without the rod.

WWII issued switches are painted

dark green, postwar switches are painted tan with markings in black.

Markings give the designation, manufacturers mark, date of

manufacture and lot number.

When the switch is assembled,

the striker and striker spring are inserted in the end of the body with

the detent facing down. The

striker is pressed back until the detent engages the sear and holds the

striker in the cocked position.

The safety pin is then passed through the holes in the side of

the body to make the switch safe.

The pressure necessary to

operate the device varies with the position the pressure is applied on

the lid. At the farthest

from the hinge pin it requires a pressure of 21 pounds, at the centre a

pressure of 50 to 60 pounds is required.

When pressure is applied to the switch the lid presses down on

the sear, when the sear is pressed down it disengages from the detent

allowing the striker to fly forward under pressure of the striker

spring. The firing pin hits

the percussion cap and fires the charge.

This switch was designed by

Experimental Station 6; a cover name for the SOE production

establishment. Originally

known as "Type 6 Release" it was designated No. 6 Mk. I when it became a

service store in 1942/43.

It remained in service with British and Canadian forces for a

number of years after the war, being used well into the 1980's, and may

still be in service. Also

listed as an issue item to the American OSS during WWII.

The switch consists of a zinc

alloy body threaded at one end to receive the "Snout, Switch, Capped,

Mk. 1". The other end is

flattened to allow it to be inserted into narrow openings.

A hole drilled in the flattened end enabled the switch to be

fastened in position. A

steel lid is hinged at the threaded end an fits over the body.

The sear is hinged at the opposite end.

The striker is formed with a sholder and firing pin at one end

and a detent cut on the other.

A safety pin hole is drilled through the body and another through

the striker.

The switch is painted dark green

with markings in black.

Markings give the designation, manufacturers mark, date of manufacture,

and lot number.

When assembled, the striker and

striker spring are inserted in the threaded end with the detent facing

up. The striker is pushed

back until the sear engages in the detent and holds the striker.

The safetly pin must be put in place or the switch will operate.

The safety pin is the only thing holding the switch in the cocked

position at this point.

When the switch is set in

position and a weight of 3.5 lbs minimum is applied to the lid, it

forces down on the lid and sear it forces the striker back slightly

releasing the safety pin.

The safety pin can then be easily removed without force.

A seven pound weight is the minimum weight recommended to hold

the switch.

This is an

electrical contact switch introduced for service in 1941.

It can be used as a pressure or pull switch.

It is used only with electrical detonators.

The main body is a

flat tin with the top soldered on and a cap on the bottom to allow a

“Battery, Dry, W, Mk. I” or a standard 3 cell flat torch (flashlight)

battery to be fitted.

It has two mounting rings soldered to either side just below the top.

There are two electrical terminals on the top of the switch.

Mounted on the flat side is the operating mechanism with a

plunger. The plunger has a

switch bar internally and a brass plate on the external end.

The plate has two holes for attachment of a trip wire and a

central threaded hole for an extension rod.

The tension required to operate the switch can be adjusted by a

ball release catch located on the side of the plunger housing.

It is adjusted by screwing in or out a setting stud.

A safety pin with a lock nut fits through the plunger housing and

plunger preventing its movement.

The safety pin cannot be removed unless the plunger is in the

neutral position and held by the ball release catch.

The minimum

operating tension is about 2.2 Kg and can be adjusted up from that.

The switch is

painted olive green and has a white star marked in the centre of the

body In addition the

positive and negative terminals are marked in red and black on the side

of the case.

When the device is

laid, pressure on the brass plate will cause it to move downward pushing

the plunger in. When the

plunger is pushed in, the switch bar will connect with contacts within

the device and complete the circuit.

If used as a pull device, a pull on the trip with will cause the

plunger to pull outward causing the switch bar to connect with two other

contacts within the device and complete the circuit.

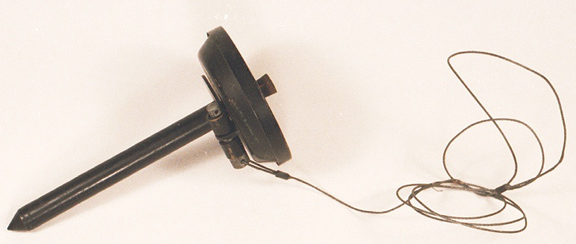

Developed by MD1 production of this switch commenced in January of 1940. It is in reality a small anti-personnel land mine that was also useful against wheeled vehicles. It was designed to be laid in paths, roads, and tracks so that when pressure is applied it would fire a bullet upwards through a man’s foot or into a tire.

The switch is

comprised of a hollow metal spike with a flange at the top end.

In the earliest versions the flange is attached to the spike, in

later versions the spike is belled out at the top and a washer slipped

over the spike being held in place by the belled out portion.

The firing mechanism is inserted into the spike.

It consists of a metal spindle with a flange at the base and an

umbrella catch at the top. A

firing spring and spring retaining sleeve are threaded over the spindle

and held in compression by the umbrella catch. Once the firing mechanism

is inserted, a striker with a short sleeve on the bottom is inserted

with the sleeve over the spindle.

When the spike is

driven into the ground, the switch is carefully loaded with a special

cartridge that rests on top of the striker with the point of the

cartridge protruding above the switch.

When a pressure of about 4 pounds is applied to the top of the

cartridge it pushes it down forcing the striker down.

The sleeve on the striker contacts the umbrella catch and forces

it in to release the spring retaining sleeve.

Once released the firing spring forces upward on the retaining

sleeve which then hits the sleeve on the bottom of the striker with a

sharp blow. The blow is

transmitted to the striker head and thus the percussion cap in the

cartridge causing it to fire.

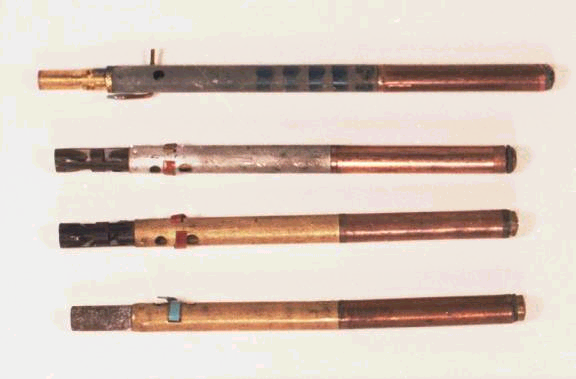

This delay switch was developed by MD1 in February 1940 and was in full production from October of 1940. It is based on the fact that Tellurium lead under load, will stretch uniformly and eventually break.

The

switch is housed in a tubular body made either of brass or steel.

The lead rod is turned down to form a small dumbbell shaped

element that is then pegged at its upper end into a brass collar.

The brass collar is then crimped into the top end of the body

tube. The striker pin is

pegged into a brass collar at its upper end which has the lower end of

the lead element pegged into it.

This brass collar is an easy sliding fit in the body tube.

The tension spring is attached to another collar that has a guide

tube for the striker attached and is crimped into the bottom end of the

body tube. The upper end of

the spring is hooked into a slot in the upper end of the striker.

At this point the spring is under tension.

An adapter or spring clip with percussion cap or 1.7 grain

detonator is crimped into the extreme bottom of the body tube.

The starting pin fits through the body and striker collar

preventing movement of the collar and thus relieves any tension being

put on the lead element. A

small clip on the end of the starting pin prevents it from falling out

accidentally. A small

plastic tab on the starting pin gives the delay time of the switch.

When the starting

pin is removed, tension is transferred to the lead element.

The lead begins to stretch and will eventually break releasing

the striker to hit the cap to ignite a fuse or fire the detonator.

This switch was also developed

during the latter part of the Second World War.

It was also on issue to the American OSS during the war.

It is likely that the American M1 Delay Firing Devicewas designed

from this switch being modified only by fitting an American Base Coupler

to it instead of the spring snout.

When the switch is to be used,

either a detonator can be fitted to the spring snout or a piece of

safety fuze. Before use the

switch must be examined by looking through the inspection holes to

ensure the striker is still held in position.

If not, the switch is discarded.

When laid the upper copper portion of the casing is crushed from

both sides, this causes the glass ampoule to break and release the

corrosive liquid. The

corrosive liquid acts on the retaining wire eventually weakening it

enough to break under the pressure of the striker spring.

When the wire breaks the striker, under pressure from the striker

spring is forced down onto the percussion cap.

The percussion cap fires igniting either the safety fuze or

detonator.

The safety strip is colour coded according to the nominal delay of the switch. When initially developed there were six different delay periods that were later reduced to the three listed below. The nominal delay times for the earlier switches were timed at 77 degrees fahrenheit. The delay strips were painted in six different colours giving delays of: black 10 min, red 19 min. White 1 hr 19 min., Green 3 hrs 10 min, yellow, 6 hrs 30 min. and blue 14 hrs 30 min. Later issues eliminated three of the delays leaving the following: A white strip gives a delay of 1.5 hours, yellow a delay of 6 hours, and blue a delay of 16-18 hours timed at 65 degrees fahrenheit. The delay times are effected by atmospheric temperatures.

The switch is normally

unpainted, the top is natural copper coloured, the bottom portion

depending on the age of the switch may be grey in the earliest models,

silver, or brass coloured.

The safety strip is painted to denote the delay times as listed above.

The switches were initially

issued in tin boxes containing 5 switches of the same delay period, the

tape sealing the box was the same colour as the safety strips.

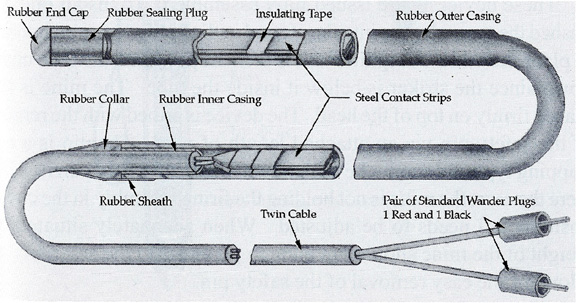

This switch was designed during

the Second World War as an electrical contact anti vehicular pressure

switch. It is designed to be

laid across a road to destroy wheeled or tracked vehicles.

Because it is an electrical switch the charge can be a

considerable distance from the switch if required.

It consists of two sections 2'

9" long connected by a flexible electrical wire 6" long.

Each section consists of two strips of brass held apart by

insulating spacers every six inches.

The strips are contained in rubber tubing closed at the ends by

rubber plugs. One section

has two additional electrical leads fitted with plugs coming out of it

to connect to the battery.

Each set comes complete with a 9 volt battery.

The battery is specially designed with sockets for the leads from

the switch and two screw terminals that will connect to an electrical

detonator.

The tubing covering the brass

contact strips is red. This

switch must be concealed or it will be easily seen on the road.

It must either be painted or covered with a thin layer of dirt or

grass. It must not be

buried.

This switch was

developed and manufactured by MD1 and introduced in 1943 as an anti-lift

device to be placed under anti- tank mines.

It was in fact a combination of the AP Switch (No. 8 Mk. I) and

Pull Switch (No. 1 Mk. I).

It was possible to use it as a boobytrap but such use was not

recommended.

When cocked, the

extension tube fits into the main housing tube and compresses the

lifting spring. The bottom

of the striker is pushed through a hole in the centre of the bush and

onto the retaining rod. The

retaining rod enters the end of the hollow spindle pushing it open so

that it cannot pass through the hole in the bush.

The safety pin holds everything together.

When laid, the weight (at

least 2.5 lbs) of the AT mine holds the head of the switch down.

If the weight is not fully down on the switch the self -trapping

safety pin cannot be removed.

If the mine is lifted, the lifting spring forces the extension

tube up and after about ¾ inch of travel the retaining rod is pulled out

of the striker allowing it to pass through the hole in the bush.

The striker spring then drives the striker up onto the primer.

When the primer fires it causes the CE pellets to fire and in

turn the main explosive filling of the device.

In turn that will likely cause the AT mine to detonate.

The device is

painted black with markings in white.

The type of explosive is marked in yellow and in addition a red

mark indicates a filled device.

This switch was developed at MD

1 by Lt. Col. Macrae near the end of the war.

Realizing that when troops were dropped behind enemy lines or

perhaps into the jungle the weight they carried became very important he

attempted to do something about it.

Carrying a dozen each of the various different switches created

more weight than necessary and he thought that if he could develop a

universal switch that combined the three basic functions it would be

easier for the troops. The

completed devices cost about 3/6d each and about 30000 were made and

issued. Unfortunately this

switch did not find favour with the troops that were to use them, they

were quite happy with the standard pull, pressure, and release switches.

While this is not actually a

boobytrap mechanism, it is included in the series.

It was designed for pinning the Type 6 Limpet mine to either

wooden or steel hulled vessels.

There is a special bracket fitted to the charge to allow the use

of the switch. It was

initially known as the “ISRB Limpet Pin-up Device”.

There are two versions, “Switch, No. 14, Charge Pinning, Mk. I –

Wood” and “Switch, No. 14, Charge Pinning, Mk. I – Steel”.

The switch is composed of two

main sections, both made of steel.

The upper section is the breech section.

It contains a striker and striker spring.

The end of the striker is threaded to accept a knurled nut that

retains the striker in its cocked position.

A safety pin fits through a reduced head of the body and striker.

The lower piece is the barrel containing a hardened steel nail

mounted on a piston. The

piston is held in the breech end by a flange which will shear on

discharge. The bottom of the

barrel is closed by a soldered brass cap and the other end is threaded

to fit into the upper breech section.

When loaded the piston is fitted with a propelling cartridge and

a separate firing pin in the form of a pipped disc.

A copper sealing disc fits over the firing pin and open end of

the piston and acts as a seal between the barrel and breech section.