Fuze No. 247 Mk. 1/2/3

Back

Fuze No. 247 Mk. 1

This fuze of British origin was manufactured

in Britain, Canada, and Australia.

It was copied by the US as an impact fuze for the T33 grenade but was not

adopted.

The fuze is of the “Allways” type, meaning

that it is designed to function on impact no matter what angle it strikes.

Originally designed for use on the No. 69 Mk. I grenade, its use was

extended to other grenades as the need arose.

Minor modifications to meet the requirements of different grenades were

made to the fuze.

The fuze body is made of bakelite.

It is internally recessed to accommodate the detonator pellet, striker,

creep spring and weighted ball. A

threaded cap closes the top and there is a flash hole in the bottom.

In the original design the bottom of the body has a small spigot

surrounding the flash hole. The

spigot was not suitable for all types of grenades and it was found to be

unnecessary so most fuzes were produced with a flat bottom.

The type with spigot are quite rare.

The centre of the body is reduced in diameter to form a seat for the

safety bolt and weighted tape. A

hole through the reduced portion allows the safety bolt to fit through into the

striker. The safety bolt is

attached to one end of an 11.5 inch tape with a lead weight at the other.

The tape is wound clockwise around the fuze body.

The top of the body is threaded to match threading in the safety cap.

The safety fits over the fuze and screws on to hold the tape in place.

A small 1.2 grain detonator is mounted in the detonator pellet.

The striker point is sheared to form two points.

The striker and creep spring fit into the detonator pellet with the

striker held in the safe position by the safety bolt once the fuze is assembled.

A lead ball fits between the top of the striker (which is concave) and

the concave bottom of the threaded cap that closes the body.

The detonator pellets may be made of brass or

zinc. The No. 247 Mk. 1A indicates

a brass pellet, the No. 247 Mk. IZ

indicates a zinc pellet.

In the No. 69 Mk. I

and No. 73 Mk. I grenades the original design with spigot could be used

but were normally fitted with the type with spigot removed.

The No. 77 Mk. I grenade could not be used with the original type fuze.

In the No. 79 Mk. I grenade, the detonator

was filled with a different composition and a one inch piece of quickmatch

inserted in the flash hole. The

fuze cap was painted green to identify it.

In the No. 82 Mk. I grenade, the weighted

tape is reduced to 4.5 inches to reduce arming time.

The cap is painted red.

| |

|

|

| |

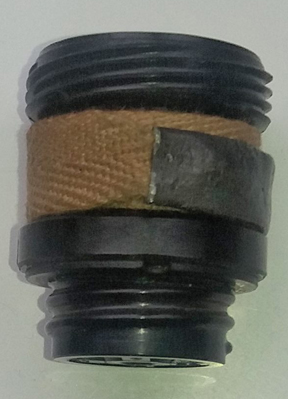

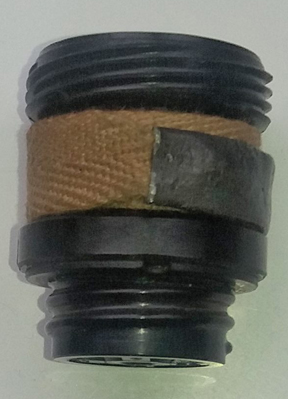

Early manufacture 247 fuze, note the spigot on

the bottom of the body |

|

|

|

|

|

|

|

| |

Early type body with spigot |

Most common type of body without spigot |

Australian manufacture |

|

| |

|

|

|

|

| |

Detonator pellets, brass on left, zinc on right |

Striker |

Difference in strikers, Mk. I on left, Mk. II on

right |

|

| |

|

|

|

|

| |

Early type weight, held on by a staple |

|

normal type weight crimped onto tape |

|

Fuze No. 247 Mk.

2

This

fuze differs from the Mk. I by having a different design of striker.

The point is shorter and is not sheared so has only one point.

The detonator pellet is made of lead antimony and has a different form of

chamber for the detonator. The

detonator is larger with 1.7 grains instead of the smaller 1.2 grain detonator

of the Mk. I.

Fuze No. 247 Mk. 3

This fuze was introduced to facilitate ease of assembly

and differs only in the body. The

cup seat for the lead ball is moulded integrally with the body and the bottom of

the fuze is closed with a screwed plug.

The fuze is assembled from the bottom instead of the top.

Thanks to Paul, here is the Mk. 3

|

|

|

|

|

| |

No. 247 Mk. 3 (Paul

Spence) |

No. 247 Mk. 3 disassembled (Paul Spence) |

|

Initially the fuzes were not marked with

anything other than the manufacturers mark.

After extension to other grenades the fuzes were marked more clearly.

The fuze is marked on the

top of the safety cap with the designation, manufacturers mark, and year of

manufacture. The markings can be

stamped or cast into the cap.

Filled fuzes have additional markings stencilled on the cap and on the exposed

surface of the tape. These markings

give the fillers initials or mark, date of filling, lot number and the letter A

or Z to indicate the material of the detonator pellet.

In addition the cap may be painted red or green as detailed above.

British and Canadian fuzes are made of black

bakelite, Australian fuzes are made of red bakelite.